A bit outside the usual

We run into a lot of different applications for the tools we sell and use for service. Most of those applications are related to industrial maintenance and reliability, but occasionally we have some that are a bit outside the usual. This post is an example of that.

A friend of mine had asked if I could help him determine if a heatsink he had made for a suppressor would reduce the cool down time significantly versus just setting it on a Nomex towel on a table. The reason he was trying to cool it down faster is that when the suppressor is used it gets very hot and he has to wait a long time until it cools down before he can pack everything up and leave the range.

He has been setting it on the Nomex towel to let it cool enough that it wouldn’t burn your hand and then used the Nomex towel to wrap it when it went in the case. He wants to be able to have it cool to the touch much quicker. He designed and machined an aluminum heatsink/stand to set it on and we went to the range to test it.

The heatsink has a large hole through the vertical center and three angled holes coming to the center from the outer diameter. It is designed so that the heat rising out the center of the suppressor will draw cool air through the small holes at the bottom and use natural convection to cool it.

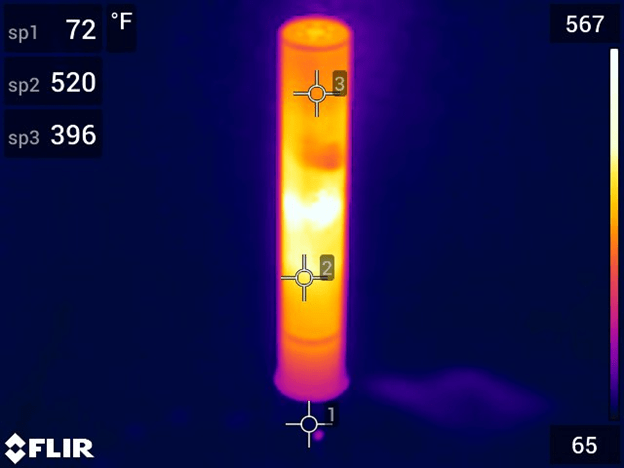

Test 1

The first measurement with the FLIR E53 was done after 70 rounds had been put through the suppressor. In Image 1 you can see the three measurement points I had setup in the E53.

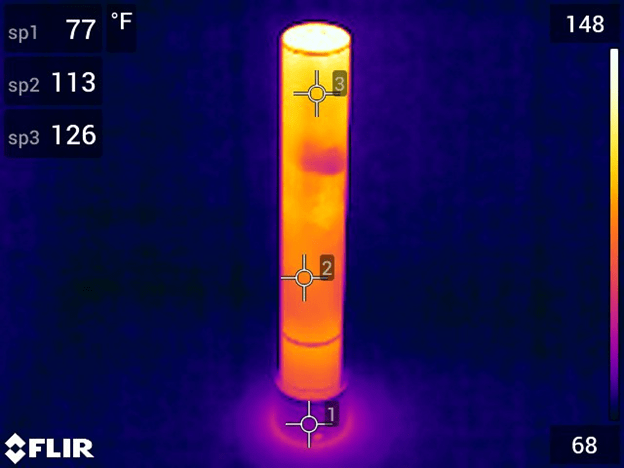

Test 2

The second measurement was done after the suppressor had cooled and another 70 rounds had been put through it. In this measurement there is no heat sink, it’s just sitting on the nomex towel.

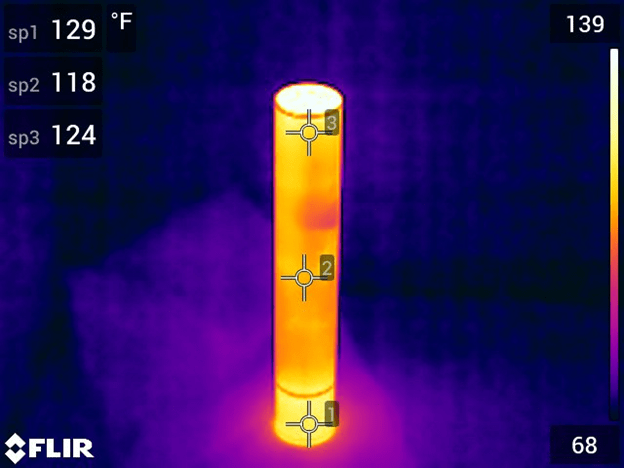

The Flir E53 (and it’s replacement, the E54) has several measurement spotmeter options. You can see in the images that we used the three spotmeter option. These three spotmeters can be moved individually around the display using the touchscreen. The other options are no spot, center spot, hot spot (it automatically finds the hottest spot in the frame), cold spot (same as hotspot, it just finds the coldest spot) and hotspot-spot (It uses the hotspot and center spot on the screen at the same time). In hindsight we should have used hotspot-spot to take the measurements since it would track the hottest point of the suppressor as it cooled. As you can see in images 1 and 2, the three spotmeter locations include the heatsink, but the heatsink is not used in images 3 and 4 so I adjusted the spotmeters so that all three were on the suppressor.